Stratasys Collaborates With Lockheed Martin to Qualify Material for Space and Aviation End-Use Parts

Report made public by Metropolitan State University of Denver delivers qualification data for Antero® 840CN03 for additively manufactured end-use parts requiring high thermal and chemical resistance, and ESD properties

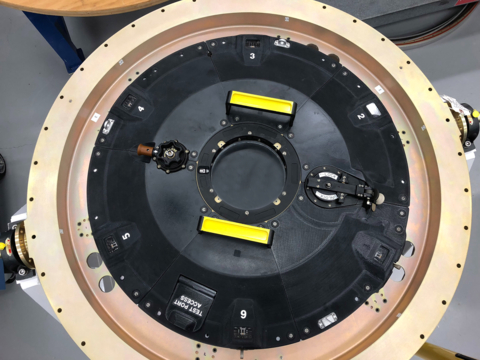

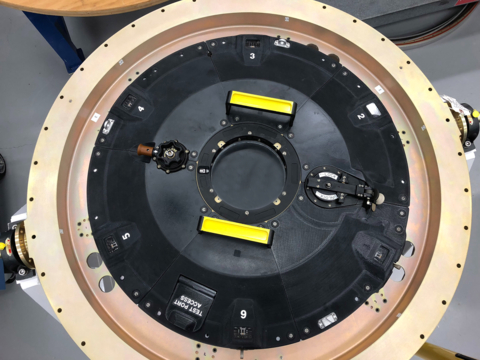

Stratasys Ltd. (NASDAQ: SSYS), a leader in polymer 3D printing solutions, today announced that it is providing the public with baseline material qualification data for Antero 840CN03 filament material in collaboration with Lockheed Martin (NYSE: LMT) and Metropolitan State University of Denver. The release of this qualification data allows those in the industry to use the material for additively manufactured aerospace parts, such as those on the Orion spacecraft, using Stratasys production-grade 3D printers.

“We want to demonstrate a new model for how industry, manufacturers and academia can collaborate to gather and release material qualification data that helps accelerate the adoption of additive manufacturing across the aerospace industry,” said Foster Ferguson, Director of Aerospace for Stratasys.

Designed for space-ready performance, Antero 840CN03 is a blended and functionalized PEKK-based high-performance, ESD thermoplastic composite material developed specifically for production-grade Stratasys FDM® 3D printers that meets ESD performance and NASA outgassing requirements while also exceeding the flame, smoke, and toxicity (FST) characteristics required for aviation applications.

During this first phase of qualification, a baseline set of data was collected by printing over 280 test coupons in Antero 840CN03 on Stratasys Fortus® F900® 3D printers at Lockheed Martin in Littleton, Colo., and Stratasys Direct Manufacturing in Belton, Texas. Coupons were tested for tensile strength properties which is a key mechanical property for design. Data collected confirmed the high performance of the Antero material as well as the consistent mechanical properties which have been previously shown in academic studies. Future phases of testing will expand to additional relevant properties, giving design engineers additional data to work within applying Antero to other part types and environments.

“We are continually looking for ways to drive innovation for flight-qualified materials and additive manufacturing is key to that endeavor,” said Cris Robertson, Associate Manager of Advanced Manufacturing at Lockheed Martin Space.

“Through our collaboration with Stratasys and MSU Denver, we have collected the data necessary to qualify Antero 840CN03 for flight parts and we are now able to expand our use of the material beyond our initial applications on the Orion vehicle.”

MSU Denver is educating and training the manufacturing workforce of the future using additive and subtractive manufacturing that can reduce costs and increase application capabilities.

“These types of research and development collaborations with leading companies like Stratasys and Lockheed Martin enable our students to be well prepared to help their future aerospace employers with adopting the latest technology in the industry,” said Mark Yoss, Director of the Advanced Manufacturing Sciences Institute at MSU Denver.

“By publishing this material qualification data, we can help move the aerospace industry forward by establishing more standards in additive manufacturing.”

Stratasys and Lockheed Martin previously worked together to collect and release material characteristics data. Most recently in 2018, as members of America Makes, the companies released allowable data for SABIC ULTEM™ 9085 resin printed on a Stratasys Fortus 900mc 3D printer. By continuing to publicly release material qualification data, the companies hope to enable further adoption of additive manufacturing in aerospace applications and use-cases.

“Through our collaboration with Lockheed Martin and MSU Denver, we hope to provide confidence in our preferred materials, demonstrate the repeatability of the F900 3D printer and deliver process documentation that supports qualification specifications for flight applications,” said Ferguson.

Through this collaboration with Metropolitan State University of Denver, full access to the data report is available to the public online. Further material testing will take place in future phases providing for full characterization of this material.

The Stratasys and Lockheed Martin teams will both be present at this year’s Space Symposium in Colorado Springs, Colo., You can also learn more about Stratasys materials and applications for the aerospace industry online.

About Metropolitan State University of Denver

As one of Colorado’s leading public universities, MSU Denver is reimagining what is possible in higher education through the power of access, diversity, excellence and innovation. Founded in 1965, MSU Denver offers high-value, real-world education to nearly 18,000 students through career- and community-focused bachelor’s and master’s degree programs. And 80% of our 100,000 alumni live and work in Colorado, advancing their communities and the state economy. Based in the heart of the Mile High City, MSU Denver’s thriving urban campus provides unparalleled access to internships and professional networks that jump-start careers.

Stratasys is leading the global shift to additive manufacturing with innovative 3D printing solutions for industries such as aerospace, automotive, consumer products and healthcare. Through smart and connected 3D printers, polymer materials, a software ecosystem, and parts on demand, Stratasys solutions deliver competitive advantages at every stage in the product value chain. The world’s leading organizations turn to Stratasys to transform product design, bring agility to manufacturing and supply chains, and improve patient care.

This content was first published on the Stratasys website.