Walter Tools: Profile milling with a significant tool life increase

Walter presents Xtra·tec® XT M5460 milling cutter with internal coolant channel

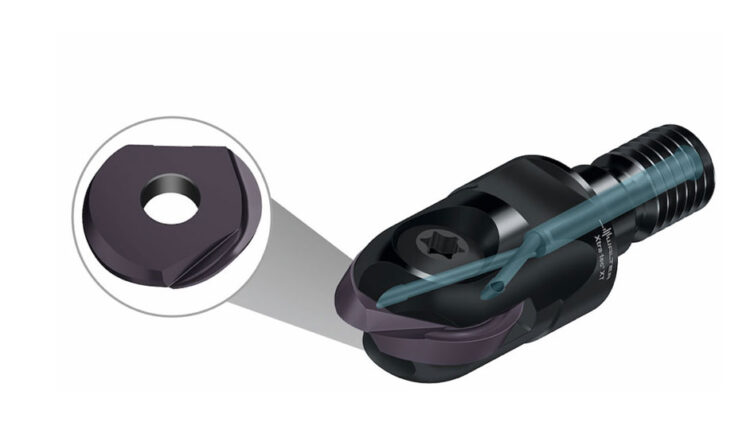

With the Xtra·tec® XT M5460, Walter is launching a new profile milling cutter on the market. It has been designed specifically for highly precise machining of freeform surfaces and deep cavities. The profile milling cutter features an internal coolant channel, which enables chip evacuation using compressed air or minimum quantity lubrication. This is necessary for deep pockets in particular, because it allows the user to blow out the chips. Walter offers the M5460 both with a Weldon and cylindrical shank, as well as with the cylindrical modular interface that is commonly used in mould and die making. When using the profile milling cutter, this potential group of customers enjoys benefits such as the possibility of continuing to use existing adaptors. As a first step, Walter is launching the milling cutter for diameters of 8–32 mm (or ⅜–1″).

The M5460 is a specialist for materials with difficult cutting properties, particularly for hard machining of steels up to 63 HRC. Alongside the geometry of the indexable inserts with extremely stable cutting edges, the key to its success is the WHH15X grade developed by Walter. This is extremely wear-resistant, therefore achieving high precision and long tool edge life. In field tests, Walter achieved increases in tool life of up to 500%. Thanks to an extensive range of cutting tool materials, the profile milling cutter can be used in steel, cast iron and stainless steels alike. This means that, in addition to mould and die making, it also offers advantages for the aerospace or energy industry. The M5460 promises high productivity with maximum process reliability.

This content was first published on the Walter Tools website.