Makino: Western Carolina Tool & Mold Ramps Up Lights‑Out Production with the Makino F5

“The Makino F5 is making it very hard to quote based on cutting time. I might quote something on 50 hours, but with the Makino, we might cut it overnight. It’s just changed a lot from where we were 20 years ago,” says Grant. But technology wasn’t the only change Western Carolina experienced. In the middle of a pandemic, they gained Gabe English as a new owner and saw a huge increase in their throughput. “In the past 2 years, our throughput doubled, and we needed to buy a piece of equipment. I had a lot of experience with Makino in the past,” English says. “There were no unknowns with Makino. I knew what kind of service I would get. I certainly understood the performance of the machine. It was worth the risk to retrain my guys on the Makino.” English knew that gaining increased performance, speed, and throughput with the Makino F5 was just the tip of the iceberg for their machining needs.

“The Makino F5 is making it very hard to quote based on cutting time. I might quote something on 50 hours, but with the Makino, we might cut it overnight. It’s just changed a lot from where we were 20 years ago,” says Grant. But technology wasn’t the only change Western Carolina experienced. In the middle of a pandemic, they gained Gabe English as a new owner and saw a huge increase in their throughput. “In the past 2 years, our throughput doubled, and we needed to buy a piece of equipment. I had a lot of experience with Makino in the past,” English says. “There were no unknowns with Makino. I knew what kind of service I would get. I certainly understood the performance of the machine. It was worth the risk to retrain my guys on the Makino.” English knew that gaining increased performance, speed, and throughput with the Makino F5 was just the tip of the iceberg for their machining needs.

Lights-Out Production

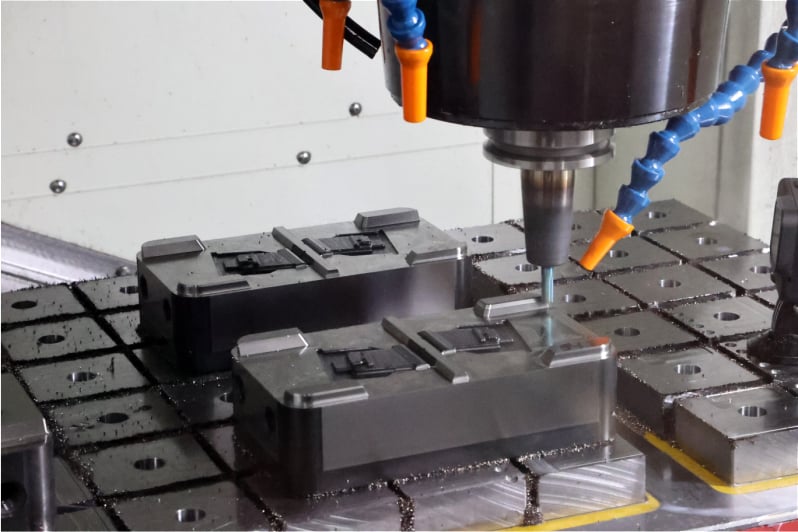

“One of the big things for us here is that we run a lot of lights out machining. We have machines running at night with pretty complex, pretty risky parts. I have confidence in Makino’s accuracy to leave it running at night and not worry about it.” English reveals that he’s never had this kind of trust with other machines. Machine specialist Tony Graham credits the Makino F5 as the driving force behind keeping up with their doubled throughput—even without a large workforce. “The Makinos are perfect for us being small because, with not as many people, it’s important for us to get a lot of run time.” Graham adds, “We can spend a small amount during the day to set up as much as we can. When we go home, that machine can run largely until we get there the next day and for long hours over the weekend. For a small shop, we can do it with a small number of people.” However, keeping up with throughput than doubled in just two years’ time isn’t strictly solved with lights out production. Western Carolina needed to machine better. And faster. This was yet another reason to choose Makino.

Faster, Smoother Cutting at High Feed Rates

English reveals that they never had the capability to the machine as fast and as accurately as they do with the F5. With a maximum feed rate of 900” per minute, it’s given Western Carolina the speed they need. “It’s sped up our processes. It’s really one of the main things the F5 opened up for us: its speed, reliability, and performance.” He adds, “One of the things that impressed me about the Makino is how versatile it was. It gave me the ability to run really small end mills all the way up to larger-sized inserts.

English reveals that they never had the capability to the machine as fast and as accurately as they do with the F5. With a maximum feed rate of 900” per minute, it’s given Western Carolina the speed they need. “It’s sped up our processes. It’s really one of the main things the F5 opened up for us: its speed, reliability, and performance.” He adds, “One of the things that impressed me about the Makino is how versatile it was. It gave me the ability to run really small end mills all the way up to larger-sized inserts.

Workforce Challenges

While technology has changed over the last 24 years, there’s been a shift in the people as well. Over the last year, they’ve lowered the average age of machinists by 30 years or more when a few guys retired, and they brought in a handful of younger apprentices. This new, younger regime includes machinist Marcus Tucker who gushes when he talks about working on the Makino F5. “I’ve had zero issues with it. I love that thing. Makino is a step up from everything I’ve ever done. If you had told me six months ago that I would be running the Makino F5, I would’ve probably laughed in your face. It’s absolutely awesome.”

More Than a Machine

Grant tells, “When we first started, we were doing a lot of CNC, but it wasn’t streamlined. We kind of got a little behind with technology, and Gabe gave us some new ideas and approaches to tooling. We made some steps forward with CNC, but after Gabe came, he helped us streamline it.” Restructuring their processes included incorporating Makino high-speed machines. However, more than just Makino’s robust technology influenced English’s decision to purchase a Makino. “One of the major factors was the service and reliability of these machines,” says English. English adds that he’s had a wonderful experience with his applications engineer.

“This is a great place and a great team. I’ve never worked in a place that works so well together as WCTM. I want these guys to have the freedom to be creative with programming skills and machining practices. It’s important here to constantly invest in new technology.” The reliability and service he gets with Makino are why Western Carolina is intending to purchase an additional 3 Makino machines over the next five years. With a grin, English says, “If I could have 4 of them on the shop floor today, I would.

“This is a great place and a great team. I’ve never worked in a place that works so well together as WCTM. I want these guys to have the freedom to be creative with programming skills and machining practices. It’s important here to constantly invest in new technology.” The reliability and service he gets with Makino are why Western Carolina is intending to purchase an additional 3 Makino machines over the next five years. With a grin, English says, “If I could have 4 of them on the shop floor today, I would.

This content was originally published on the Hwacheon website.