KUKA: Tradition Meets Technology-Robots Provide Support in Joineries

In joineries, we can see how state-of-the-art technology complements traditional craftsmanship in a meaningful way. About ten years ago, the Eigenstetter joinery in Rehna, in the northwest of Germany, was faced with a huge project – a KUKA robot was the solution. To this day, the metal giant, which can carry up to 500 kg, mills large-volume components in a cell with the utmost precision. A circular front door with a stitched arch for a round tower: When the joinery received this order in 2011, it needed a special solution.

New Robot Colleague Enables Larger Projects

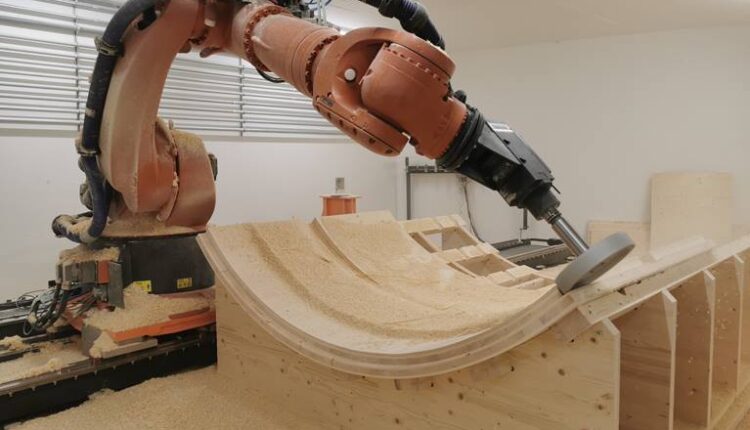

So they looked around for alternatives and, by chance, came across a robot. “We found a supplier in Tyrol that had a KUKA robot,” he recalls. With the help of its new robotic colleague, the Decker joinery has now been able to tackle even larger projects. “We were able to mill parts for huge tree houses, as well as elliptical staircase stringers or unusual free forms,” Decker explains. The Decker joinery has 42 employees and has been in operation worldwide for about 40 years.

Future Potential Follows Initial Skepticism

“Instead of laying off employees, we actually hired two more,” Decker says. Other joineries from the surrounding area would have special parts made by them. In addition, he says, the company has become more attractive to trainees, who also learn CNC skills in a four-year carpentry technician training program. Decker’s conclusion on the acquisition of the robot: “You really have to dare to take this step – and also become a little inventive yourself. But it’s worth it.”

Eigenstetter is already working on the next project with the local Fraunhofer Institute. “We want to use smaller robots in medium series on carpentry machines such as a milling machine or a belt sander according to the part-to-tool principle,” he explains. The parts to be machined are placed in the machines by robots. He sees great potential for the future in this area.

This content was originally published on the KUKA website.