Mastercam: CNC Software Europe Reaches Milestone, Celebrates Anniversary

Mastercam, headquartered in Tolland, Connecticut, is celebrating the tenth anniversary of the opening of its Swiss office. CNC Software Europe, SA was opened in April 2011 as a development office primarily to support the market for small precision turned parts. Today, the office is now 10 years old and is a part of several teams within CNC Software, Inc., contributing across the entire suite of Mastercam products.

According to Gary Hargreaves, CNC Software Chief Legal Officer, “We opened the development center in Switzerland because of our commitment to the Swiss market. Hiring the right talent in Switzerland gave us the team to successfully push forward in this growing market. The Mastercam Swiss Machining Solution is a great complement to the existing suite of Mastercam products.”

Located in Porrentruy, Switzerland, CNC Software Europe allowed the company to access the expertise available in the Jura region of Switzerland, known as the birthplace of Swiss machining and is known for watchmaking, medical and has many companies manufacturing products with small, precise moving parts.

According to Matthieu Saner, Manager, Software Engineering, “In addition to Swiss machining expertise, the Swiss office contributes today to many features being developed in Mastercam, as well as in post processor development.” Saner continues, “Some research projects in the field of manufacturing automation and Industry 4.0 are being completed in partnership with Swiss universities driven by the Swiss office. Our office also participates in local internship programs to provide opportunities for students to become familiar with the development of leading software in the world.”

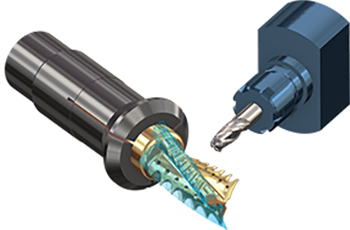

Swiss turning machines can be highly complex with many operations happening simultaneously. The ability to accurately drive these machines requires software developed specifically for this type of machine. Mastercam’s Swiss Solution combines Mastercam Mill and Lathe with an optimized post-processor to give users a reliable set of tools to program parts for their Swiss machines.

The market for Swiss-type lathes has been increasing steadily. In addition to the shop that specializes in Swiss machines creating small, precision parts, the use of products like Mastercam Swiss Machining Solution has allowed the job shop to expand into this market. Many existing Mastercam customers are now buying Swiss CNC machines to produce smaller lots of parts and provide faster turnaround to their customers.

This content was originally published on the Mastercam website.