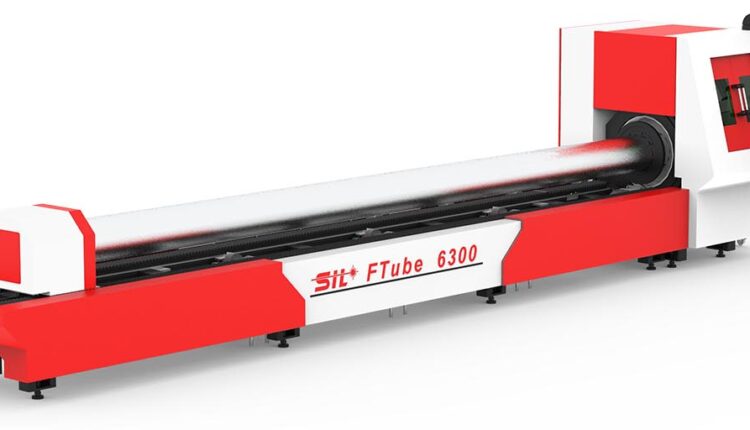

Fiber Laser Pipe Cutting Machine by SIL

Description

Laser pipe cutting machine incorporates space-saving design and ease of use. Its high cutting speed and very low operating cost make it the most affordable system on the market. The lightweight motion system allows excellent positioning accuracy while maintaining cutting speeds that are the highest in its class.

The application is for cutting Mild Steel Pipe, Stainless Steel Pipe, Aluminium Alloy pipe, copper pipe, Brass pipe ( Square Pipe, Round pipe, Rectangular pipe, C Channel, H Channel ), etc.,

Specifications

Features

- Efficient cutting of square and rectangular sections with a sliding way mounted cutting head.

- Low noise levels and the very best cut quality.

- The optimum working parameters for the best possible machine performance.

- The material feed system and vice geometry assure the most positive clamping of the material during the cutting cycle, whether the material is a thin wall delicate tube or through a thick wall tube.

- During the material feeding process, the material is lifted away from the vice bed and vice jaws to prevent the material surface from being marked or scratched.

- The cutting line has been designed to operate either as a standalone system or fully integrated into a complete automatic line controlled by one CNC programming unit.

Technical Specification

| Laser Power | W | 1/2/3 |

| X/Y Speed | m/min | 100 |

| Rotary Diameter | mm | 160/220/320 |

| Machine Weight | Kg | 3500 |

| Cutting range | mm | 3000/6000 |

| X-Axis Stroke | mm | 400 |

| Y-Axis Stroke | mm | 3000/6000 |

| Z-Axis Stroke | mm | 220 |

| Positioning Accuracy | mm/m | ≤±0.05 |

| Max Idle Speed | m/mm | 60 |

| Repositioning Accuracy | mm | ≤±0.05 |

| Power | V/Hz | 380/50 |

| Cutting Acceleration | G | 0.5 |

| Controller | Cyprus | |

| Weight | Kg | 3500 |

Applicable Industries

Fitness equipment, sporting goods, petroleum pipelines, construction machinery, passenger car manufacturing, Locomotive manufacturing, agriculture and forestry machinery, special vehicles, household appliances manufacturing, laser external processing services, and other machinery manufacturing pipe process industry.

The auto-feed enables for perfect slicing of the job.

Finished job command offers to cut pipes without wastage.

Cut cross-section to slice the pipe in the desired location and also reduce the waste to a minimal amount.

Hiding a layer enable to reduce lower number of outer slice

Pneumatic or electric job holding provides the proper position of the pipe in 3 Dimensions. Tube types Round, Oval & Rectangular

Efficient cutting of square and rectangular sections with a sliding way mounted cutting head.

Low noise levels and the very best cut quality.

The optimum working parameters for the best possible machine performance.

The material feed system and vice geometry assure the most positive clamping of the material during the cutting cycle, whether the material is a thin wall delicate tube or tough, thick wall tube.

During the material feeding process, the material is lifted away from the vice bed and vice jaws to prevent the material surface from being marked or scratched.

The cutting line has been designed to operate either as a stand-alone system or fully integrated into a complete automatic line controlled by one CNC programming unit.

This content was originally published on the SIL website.