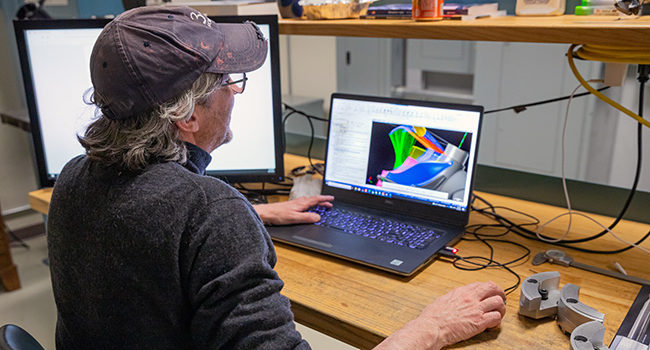

5 Ways Mastercam 2023 Makes Your Life Easier

Mastercam 2023 is full of new, useful tools that can make your day-to-day easier. Here are the top five you need to know.

Detecting Undercut Stock When Machining

In Mastercam 2023, achieving optimized motion is a matter of turning on a switch. The Dynamic OptiRough and Area Roughing toolpaths can now be aware of undercut stock conditions when rest machining. This results in improvements to the toolpath motion including less air cutting.

Consolidating Multiaxis Toolpaths

One toolpath now unlocks all Multiaxis operations and surfacing applications. For example, Unified Multiaxis can create a “morph between two curves” toolpath by selecting a curve in two separate cut pattern groups, then selecting the Morph cut pattern style. Unified Multiaxis allows for far more flexibility in cut pattern when programming Multiaxis all within a new advanced feature set and consolidated, easy-to-use interface.

New B-Axis Contour Turning Toolpath

B-Axis Contour Turning is a new toolpath introduced in Mastercam 2023 that allows for rotation of the B-Axis while the Lathe or turning tool is cutting. This means fewer tool changes and less cycle time. B-Axis turning enables you to dynamically tilt your turning tool on a B-Axis Mill-Turn machine environment as needed to access undercut or difficult-to-reach areas of the part. Areas that would have taken multiple tools and resulted in blends are now possible with one tool in Mastercam 2023. This results in a superior finish with fewer tool changes in less cycle time.

More Powerful and Flexible 3D Roughing Linking

Mastercam 2022 introduced the new Linking Parameters page for finishing 3D high-speed toolpaths, and now Mastercam 2023 has expanded this effort to the Dynamic OptiRough, Area Roughing, and Horizontal Area toolpaths. Control and optimize your air cuts with the new linking parameters in OptiRough, which allow for greater efficiency in roughing toolpaths when transitioning between passes or when in air. No matter how efficient the roughing program, air cuts make up a significant portion of cycle time and the ability to control and optimize this motion is just as critical as getting feeds and speeds set correctly.

Equal Scallop Stock Awareness

Equal Scallop is now a fully stock aware, semi-finishing toolpath that now identifies material left in corners and will machine with a single pass or with multiple passes to ease into the material. With this new functionality, simply specify a previous roughing tool and a max engagement and Equal Scallop automatically creates iterative and safe step in passes to prep for finish. This functionality essentially turns Equal Scallop into a stock aware, semi-finishing toolpath.

This content was first published on the Mastercam website.