A reverse engineering project typically starts in the metrology department with a 3D scanner capturing an object’s physical dimensions. Success, however, depends on being able to transform the shape and the dimensions into the final object you want or need. You have to remember, the file itself is only a few bytes. It is not the valuable final asset, simply the data required to produce it, evaluate it or copy it.

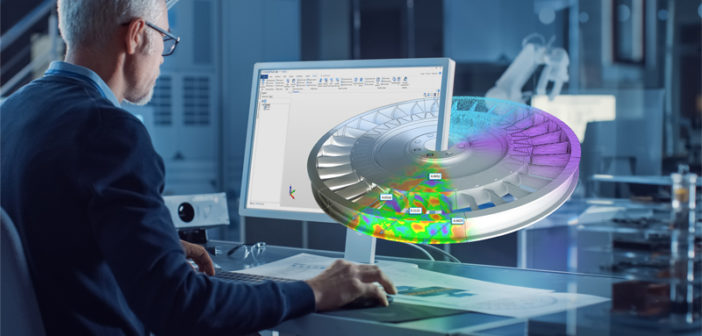

How quickly, easily and well this can be done is determined by the engineer and the reverse engineering package. When Hexagon developed the new reverse engineering software, REcreate, the focus was on delivering a single seamless working environment that makes it easy to go from an initial 3D scan through to creating a manufacturable CAD model.

REcreate reverse engineering software also had to be accessible to as many users as possible across design, production and inspection teams. In addition, it had to be powerful enough to address any reverse engineering application, whether reconstructing a legacy part; ensuring a precise fit for new components; creating a CAD for parts when none exist or updating design files to reflect changes that occurred during manufacturing or prototyping.

Here are just a few of the ways in which REcreate delivers a flexible, powerful and intuitively simple user experience:

- Design intent

Reverse engineering is not as simple as reproducing a scan. If anything, the process is much closer to the act of translation, with the trick being to create something that looks like the scanned part while using enough intelligence to adapt it to a new use or environment. Take, for example, the reconstruction of a 50-year-old legacy part. Typically, the precise original dimensions will have been lost, with previously sharp edges worn and rounded down by use. To complicate matters, there is unlikely to be any knowledge of the usability and manufacturing constraints factored in by the original designer.

By respecting design intent, REcreate enables users to modify all aspects of a model with the knowledge of which manufacturing process is going to be used and what boundary conditions they require to create a coherent and functional design. This gives users the freedom and confidence to push and pull the model to create an optimal design and give a new lease of life to an old part.

- Direct modelling

Reverse engineering needs to be agile and versatile, allowing users to make improvements as they go along rather than having to shoot for perfection from the outset. With REcreate Hexagon wanted to avoid the rigidity of modelling using a history tree, for example, or the difficulty of surface-based modelling methods. The answer is a direct modelling system. With REcreate it is easy to move smoothly from point cloud management through to the creation of meshes, surface models and solids all within a single design environment. A mix of modelling capabilities that encompass surfaces as well as solids makes it possible to draft angles and undercuts that are cleanly square and cylindrical rather than almost so. And because the direct modeller links to scanning hardware, it is easy to scan straight into REcreate or import meshes.

- Standalone CAD

REcreate comes with a full, powerful CAD system that allows users to create CAD models which are ready to use in manufacturing. Its numerous functions include the ability to create accurate CAD models from fragmented data.

- 2D drawings

2D drawings remain widely in use in workshops around the world. This means that no matter how sophisticated your own digital design and manufacturing systems, you are likely to have to deal with them. REcreate’s CAD system helps you do this with functions that include the creation of 2D drawings

- Manufacturability

It’s not enough to come up with a model of a part that looks great. You also must be able to manufacture it in a timely, efficient and cost-effective manner. With REcreate’s analysis tools users can interrogate 3D models and validate whether they are manufacturable before exporting as CAD or STL for computer-aided manufacturing (CAM) or additive manufacturing processes.

This content was originally published on the Hexagon MI website.