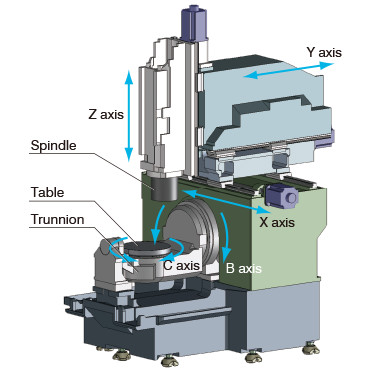

5-Axis Vertical Machining Center UNIVERSAL CENTER MU-4000V

A trunnion table for high accuracy, ease of use, and compactness

The MU-4000V has a very rigid roller gear cam suited to high-speed drive on the trunnion table B-axis, and a direct drive motor that produces high torque even at low speeds on the C-axis. This makes it possible to achieve both high-speed and high-accuracy machining.

High-speed

- B axis: 50min-1

- C axis:120min–1(Standard)

1,200min-1(Optional)[turning mode]

Indexing accuracy*

- B-axis indexing accuracy/repeatability: ±1.78 sec/±0.50 sec

- C-axis indexing accuracy/repeatability: ±2.26 sec/±0.12 sec

Note: The data shown are actual data but do not represent guaranteed accuracies.

Easy-to-use 5-axis machine from well-considered design

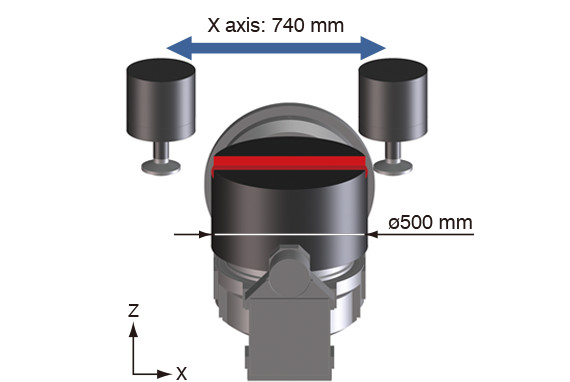

The large working range for the applicable workpiece machining area is large enough to handle workpieces with a maximum diameter of ø500 mm and a maximum height of 400 mm. Tools can also reach the end of workpieces even with the table inclined at various angles, making 5-axis machining possible over a wide range.

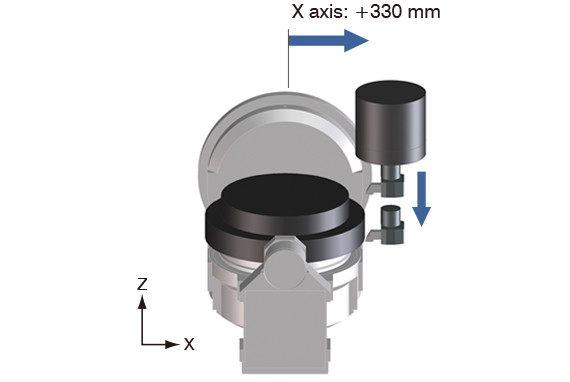

Tools can be changed even with the trunnion in a swung position, contributing to reduced cycle times and improved machining accuracies.

Large machining area

- Swing range B axis: +90º to −120°, C-axis: 360º (infinite rotation)

- Max workpiece weight: 300 kg

- Max workpiece size: ø500 × 400 mm height

Max workpiece diameter with large X-axis travel (ø500) peripheral cutting is possible

- Even the largest workpieces are machined with capacity to spare

![Even the largest workpieces are machined with capacity to spare]()

- Visibility of the cutting edge at the time of cutting also excellent

![Visibility of the cutting edge at the time of cutting also excellent]()

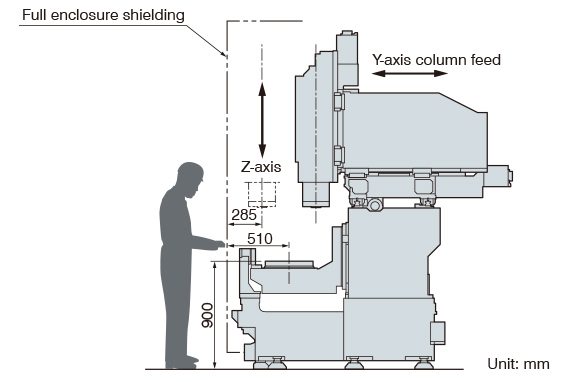

- Good access reduces operator burdenGood access of 515 mm to the center of the table is achieved by approaching from the trunnion axial direction.

Access to the spindle is also good, reducing operator burden during machining preparation and increasing work efficiency.![Good access reduces operator burden]()

- Better visibility of machining status BC table structure allows confirmation of the workpiece status at an angle of 120° and the front door has a large window. LED lamps are used for bright, reduced-flicker lighting within the machining compartment, improving the visibility of machining status.

![Better visibility of machining status]()

High-spec basic performance delivers high-efficiency machining high cutting capability with high output motors motor with maximum torque of 199 N-m is used on the spindle. Machining time can be shortened with high-efficiency machining. The use of a high torque motor on the turning spindle also gives high turning capacity.

- Standard spindle

- Speed: 15,000min-1(With turning specs: 12,000min-1)

- Max output: 22/18.5kW (10 min/cont)

- Max torque: 199/146N・m (5 min/cont)

![Standard spindle]()

- Turning spindle (Optional)

- Table (turning spindle) spindle speed: 1,200min-1

- Max output: 15/10kW (15 min/cont)

- Max torque: 477/318N・m (15 min/cont)

![Turning spindle (Optional)]()

Machine specifications

| Item | Unit | MU-4000V | MU-4000V-L Turning Specs | |

|---|---|---|---|---|

| Travels | X axis (spindle ram) | mm (in.) | 740 (29.13) (+20 (0.79) ATC movements) | |

| Y-axis (spindle ram) | mm (in.) | 460 (18.11) | ||

| Z-axis (spindle ram) | mm (in.) | 460 (18.11) | ||

| B axis (trunnion rotation) | deg | +90 to -120 | ||

| C axis (table rotation) | deg | 360 (infinite) | ||

| Table surface to spindle nose | mm (in.) | 120 to 580 (4.72 to 22.83) | ||

| Table | Table size | mm (in.) | ø400 (15.75) | |

| Max work size | mm (in.) | ø500 × H400 (ø19.69 × H15.75) | ||

| Floor to tabletop | mm (in.) | 900 (35.43) | ||

| Max load capacity | kg (lb) | 300 (660) | ||

| Turning spindle speed | min-1 | – | C axis: 1,200 | |

| Spindle | Spindle speed | min-1 | 15,000[20,000, 25,000] | 12,000 |

| No. of spindle ranges | Infinitely variable | |||

| Tapered bore | 7/24 taper No.40 [HSK-A63] | HSK-A63 | ||

| Bearing dia | mm (in.) | ø70 (2.76) | ||

| Feed | Rapid traverse | m/min (rpm) | X-Y-Z: 50 (1,969) | |

| Rapid traverse | deg/min | B: 18,000 (50min-1) C: 43,200 (120min-1) | ||

| Cutting feedrate | mm/min | X-Y-Z: 1 to 50,000 | ||

| Motors | Spindle (10 min/cont) | kW (hp) | 22/18.5 [30/22, 15/11] (30/25 [40/30, 20/15]) |

22/18.5 (30/25) |

| Feed axes | kW (hp) | X-Y-Z: 3.5, B: 4.6, C: 6.7 (X-Y-Z: 5, B: 6, C: 9) | ||

| ATC | Tool shank | MAS BT40 [HSK-A63] | HSK-A63 | |

| Pull stud | MAS 2 [-] | – | ||

| Tool capacity (magazine) | 32-tool (chain) [48-tool, 64-tool: chain, Over 64-tool: matrix] |

|||

| Max tool dia (w/adjacent / w/o adjacent) | mm (in.) | ø90/ø125 (ø3.54/ø4.92) | ||

| Max tool length | mm (in.) | 300 (11.81) | ||

| Max tool weight | kg (lb) | 8 (18) | ||

| Maximum tool mass moment | N-m | 7.8 | ||

| Tool selection | Memory random (matrix magazine is fixed address system) | |||

| Machine size | Height | mm (in.) | 2,950 (116.14) | |

| Floor space W x D | mm (in.) | 2,399 × 3,248 (94.49 × 127.87) | ||

| Weight | kg (lb) | 9,700 (21,340) | ||

| CNC | OSP-P300MA | OSP-P300SA | ||

This content was originally published on the Okuma website.