3DTIMONTM Plastic Moulding Simulation Tool from Toray Engineering D Solutions Co., Ltd.: DesignTech

3DTIMONTM is a CAE solution used for manufacturing molded plastics and composite materials. 3DTIMONTM has been developed by Toray Engineering Co., Ltd. a company providing innovation in manufacturing through plant construction, production equipment, and related software. The company has been established in Japan in 1960 and is headquartered in Tokyo. 3DTIMONTM is a niche CAE simulation tool for Plastics Moulding. It has a history of 35 years of development, and the Toray Group – a material manufacturer that operates around the world – has poured in all their manufacturing experience in perfecting the software. 3DTIMONTM, the industry-standard plastic molding simulation tool is useful for a wide range of products – from injection molding to molding of advanced materials.

DesignTech Systems, India is an Exclusive Business Partner of Toray Engineering D Solutions Co. Ltd. in India for 3DTIMONTM.

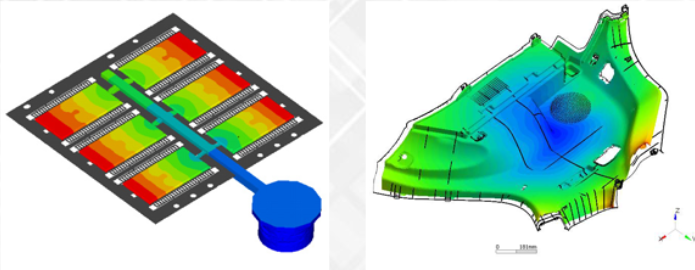

3DTIMONTM Solutions

Unique tetra mesher

- A patented meshing pre-processor is a built-in tetra mesh generator that uses bubble mesh generation theory for optimum meshing.

Measures against cosmetic defects

- Predicts weld line and sink mark. Develops measures to review gate position and product thickness to reduce the number of mold modifications and trials

Warpage reduction

- Analyzes main factors of warpage and develops countermeasures

- Derives product shape and gate location to reduce warpage

Optimization for lightweight design

- Optimizes molding conditions with existing machines by using results of filling patterns and pressure

Cycle time optimization

- Predicts product temperature and mold temperature with three-dimensional cooling channel

- Checks the temperature distribution and considers the appropriate cooling channel layout and product thickness.

Evaluation of quality and reliability for molded product

- Predicts deformation due to residual stress and thermal influence

- Evaluates product quality through heating techniques such as annealing, painting, heat cycle testing

Various optimization functions

- Proposes parameters such as optimum gate position and product wall thickness and improves the efficiency of analysis work

Evaluation of strength

- Predicts nonlinear properties from analysis results of fiber orientation

- Challenges marginal design by conducting highly accurate strength evaluation in combination with structure analysis

Direct Fiber Simulations (DFS)

- Forecasts bending and breaking of reinforcing fiber, fiber length, density distribution

- Performs high accuracy and strength evaluation of warp deformation analysis

Unique extensional functions of 3DTIMONTM

- AMDESS for 3DTIMONTM enables automatic design optimization. For example, it can find out optimum shape and thickness to reduce warpage, optimum gate position to shift the weld position, etc.

- Ejector Pin Evaluation Tools – Buckling Risk / Buckling Load

The system based on the concept of fast & easy is able to quickly check the analysis results by setting analysis conditions according to workflow. - Thermosetting resin analysis – 3DTIMONTM-ReactiveMOLD

Corresponds to injection molding and transfer molding to predict filling, fiber orientation, and warping for use in automotive electronics - Compression moulding analysis – 3DTIMONTM-CompositePRESS

Predicts filling, fiber orientation, and warp deformation in thermosetting SMC and BMC molding, as well as thermoplastic stamping molding. It can be utilized for studying weight reduction by replacing metal parts.

This content was originally published on the Designtech website.